Product Center

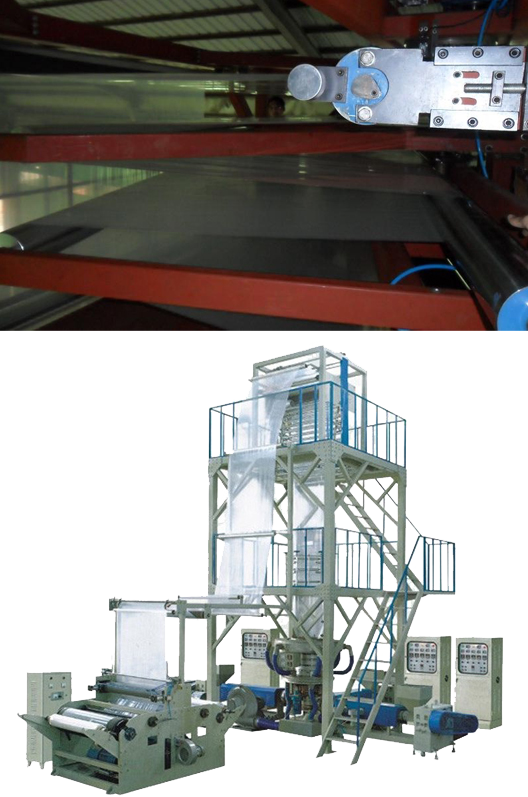

Three Layer Co-Extruding Traction Rotation Film Blowing Machine

- Product introduction

-

Product Usage:

Three layer co-extrusion rotating internal bubble cooling film blowing machine unit is a new products of our company,research and development according to the needs of the market,designed to absorb the domestic and foreign similar products’ advanced technology,It is suitable for HDPE,LDPE,LLDPE and other plastic raw materials,applied to produce shrink film,liquid film,protective film,cable membrane,compound film base material,adhesive polymer film,multifunctional industrial packaging film and other high quality plastic packaging film. This film can meet the requirements of high accuracy,high speed for color printing, compound and coating products.

Product Features:

1. The traction which replaces the die head can make vertically a full 360 degree reciprocating rotation. It simplifies the structure of die head, and avoids the problem of escaption of material, and quality problems as the different size of film roller and the different degree of tightness. It makes sure the flatness of reeling.

2. The cooling system in IBC film bubble improves the clarity of film and quality, the system can adjust the air quantity by controlling the speed of draught fan, which control the stability of film diameter with high precision, meantime due to the simultaneous cooling outsides and inside of film bubble,the machine units can improve a lot in productivity.

3. EPC photoelectric correction system can rectify automatically the direction of traction and guarantee the uniform of film reeling.

4. High-precision die head and efficient double vents air ring cooling system make sure the uniform thickness of film, leading to the high percent of pass products The film is of well barrier property,retaining freshness,moisture –proof,frost prevention,pickles,fresh milk,drink,medicine,etc.

Technical Parameters:

Model RFD-1200 RFD-1500 RFD-1800 RFD-2000 RFD-2200 Max. folding width(mm) 1200 1400 1600 1800 2000 Film thickness(mm) 0.02-0.10 0.02-0.10 0.02-0.10 0.02-0.10 0.02-0.10 Max. output(kg/h) 130 160 180 220 280 Raw material MLLDPE, LLDPE, LDPE, EVA Screw diameter(mm) Φ45/Φ55 /Φ45 Φ55/Φ65 /Φ55 Φ55/Φ75 /Φ55 Φ65/Φ80 /Φ65 Φ75/Φ90 /Φ75 Screw L/D ratio(L/D) 30:1 30:1 30:1 30:1 30:1 Screw max. rotation speed (r/min) 90 90 90 90 90 Main motor power(kw) 15/18.5/15 18.5/22/18.5 18.5/30/18.5 22/37/22 30/45/30 The way of screen changing of extruder Manual twin-station changing screen quickly or hydraulic pressure auto Die structure Spiral Mandrel Feeding Structure(IBC system) Air ring structure Labyrinth structure with double air channel Film turning mode Horizontal Anglo of reversing ±360° Roller width(mm) 1200 1500 1800 2000 2200 Traction power(kw) 2.2 2.2 2.2 2.2 3.0 Winding mode Back to back winding Winding power 1.5 1.5 2.2 2.2 2.2 Mechanical linear speed (m/min) 45 45 45 45 45 Installing Power(kw) ≈100 ≈120 ≈135 ≈165 ≈185 Dimension(L×W×H)(m) 9×6×8 9.5×6.5×9 10×7×10 10×7×11 11×7.5×12